A production controlled at 100% for an indispensable security

To manufacture safe and reliable products destined to the general public is a big responsibility.

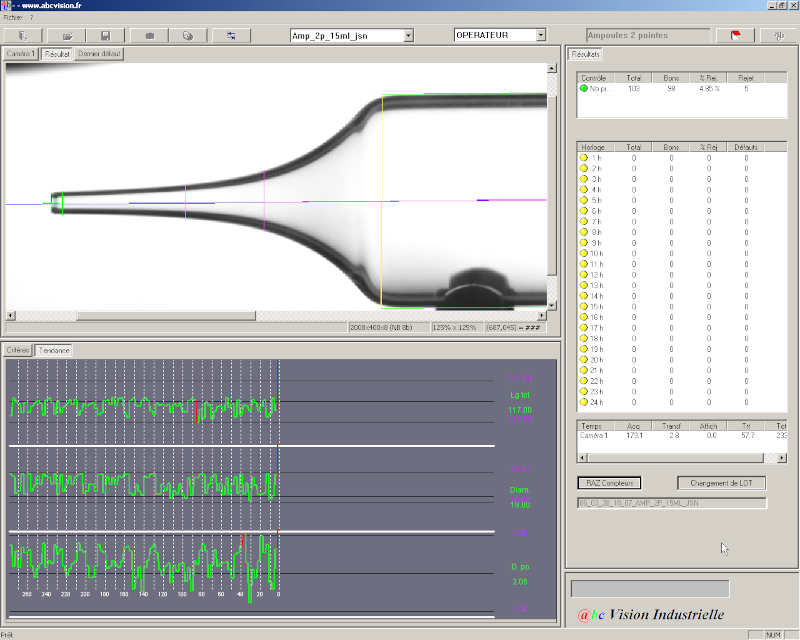

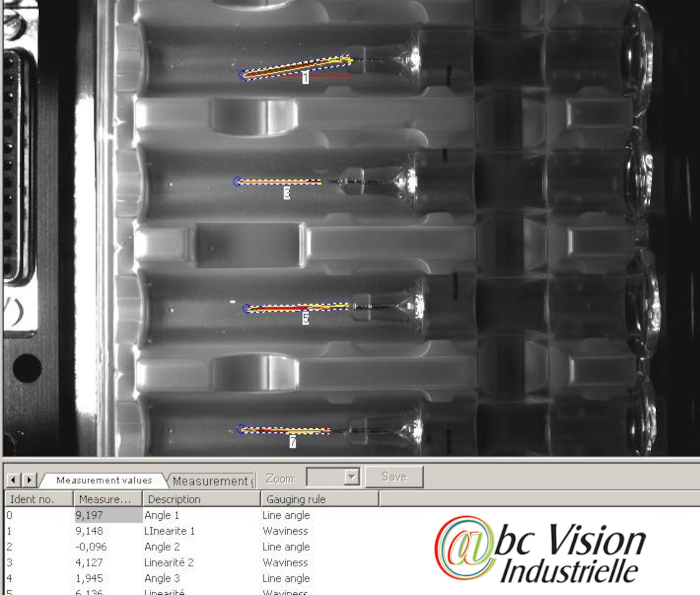

Vision machine allows pharmaceutical sector to certify a traceable and secured production.

Our solutions comply with 21 CFR part 11 standard.