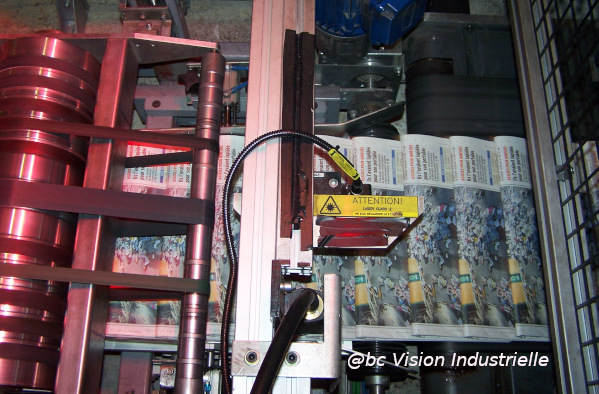

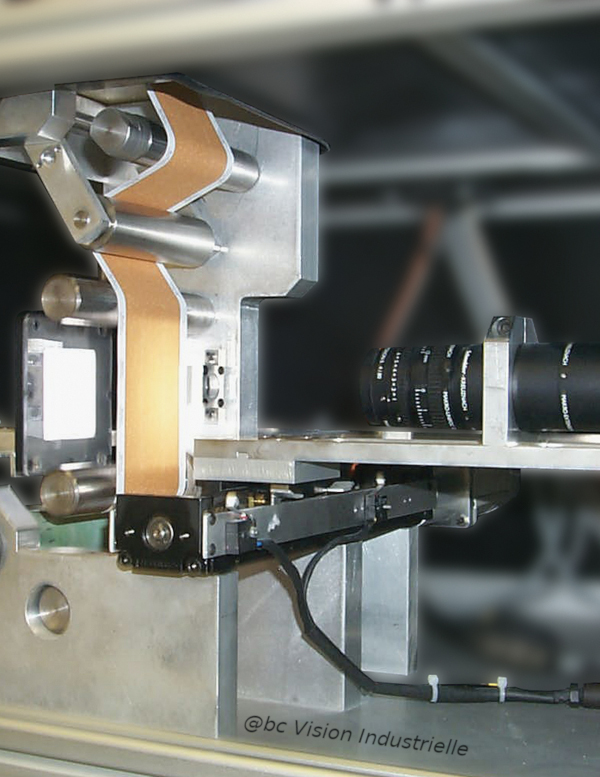

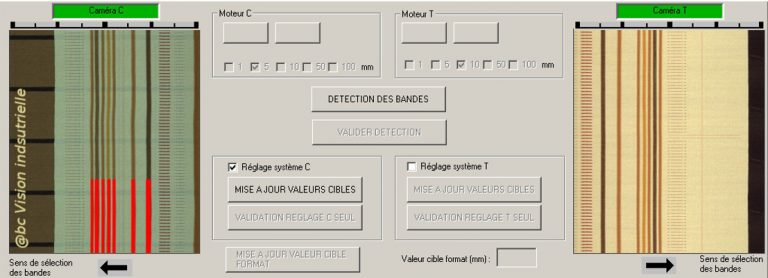

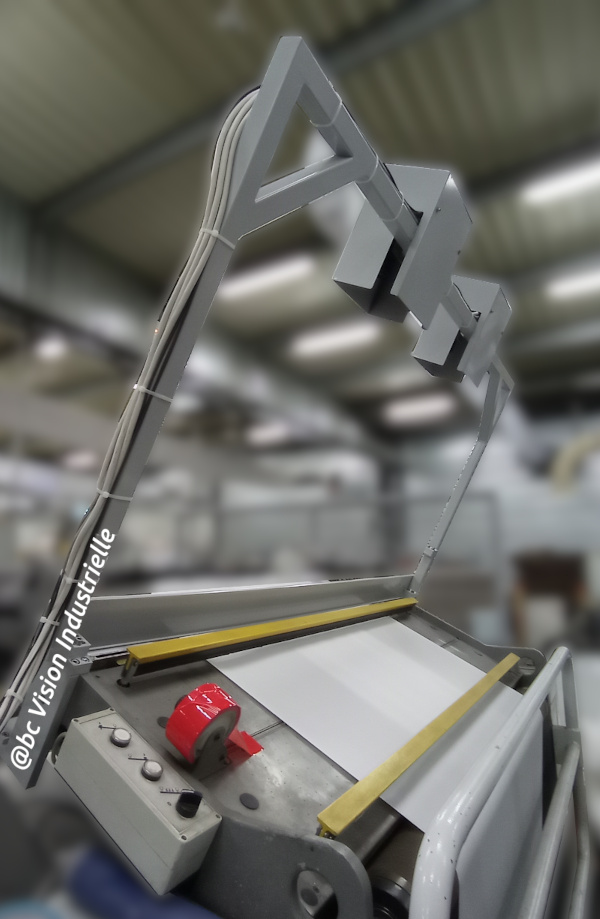

100% Vision control on paper width.

Precision and velocity constraints make Machine Vision a must-have tool to control paper.

High production rates make visual control difficult or impossible. Yet, this control is essential as a statement of quality, to adjust a delicate process or to identify production risks.

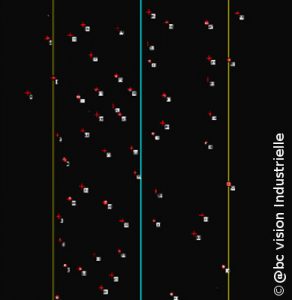

This is where Machine Vision takes all its sense in making possible a systematic production control: control of markers, micro-perforations, machine stuffing… everything is under control!