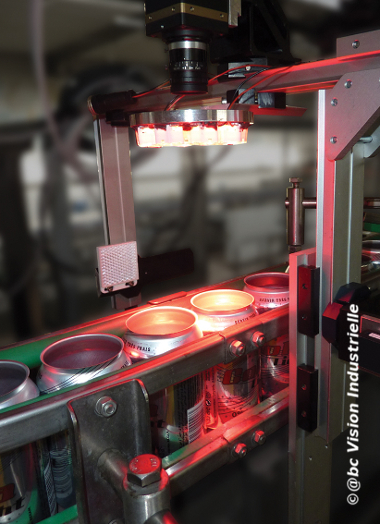

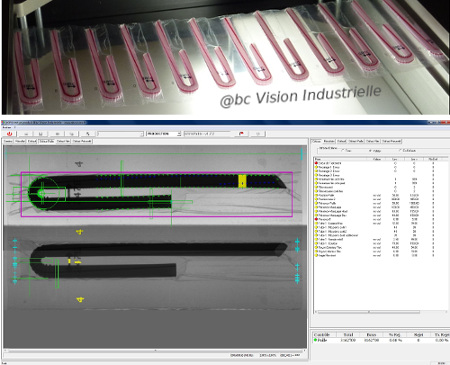

100% quality control for a 0 defect packaging.

Checking the quality of packaging to certify a perfect product -both technically and cosmetically-to final customer: maximum brand image security.

The message is clear: your customer is important and you take care of him!