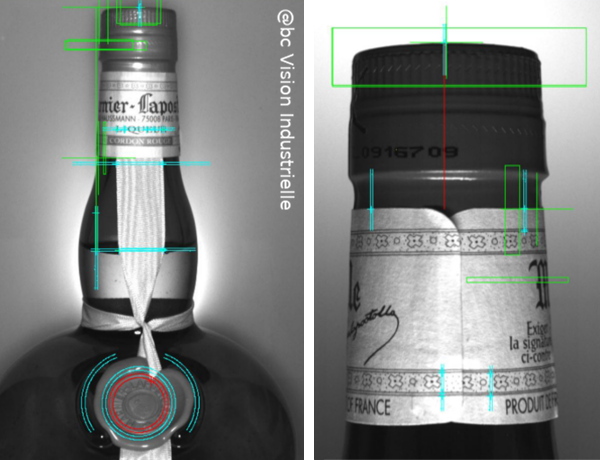

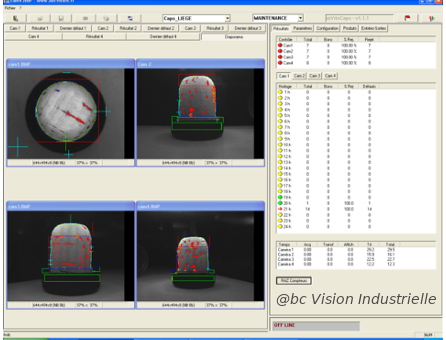

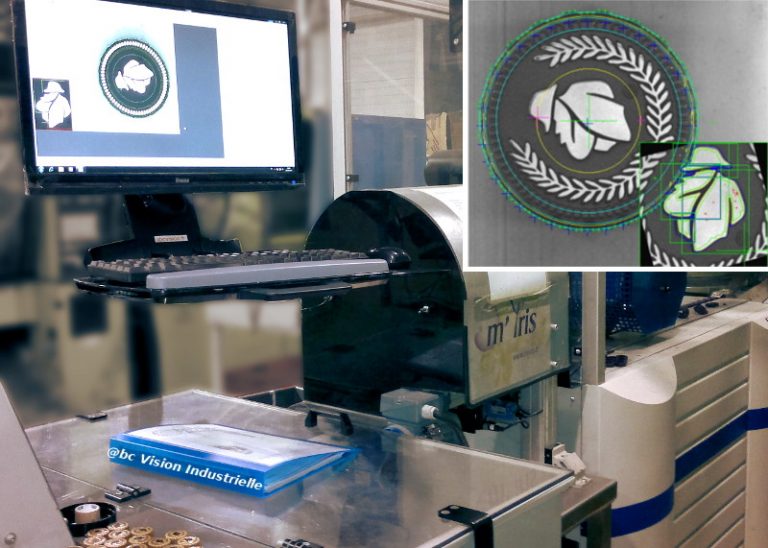

Control of the entire bottle: level, cap, label, turbidity…

Guaranty your brand image and the security of consummators is a crucial issue.

Your customers require a perfect quality on bottles, both aesthetically and technically.

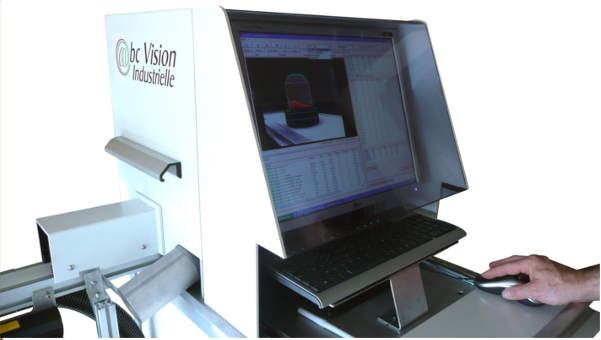

We have solutions for an 100% control on bottling lines: from the simple label presence control to complete facing verification according to the need.

We combine cameras, sensors and custom lighting to offer you a complete control system which best fit your need.