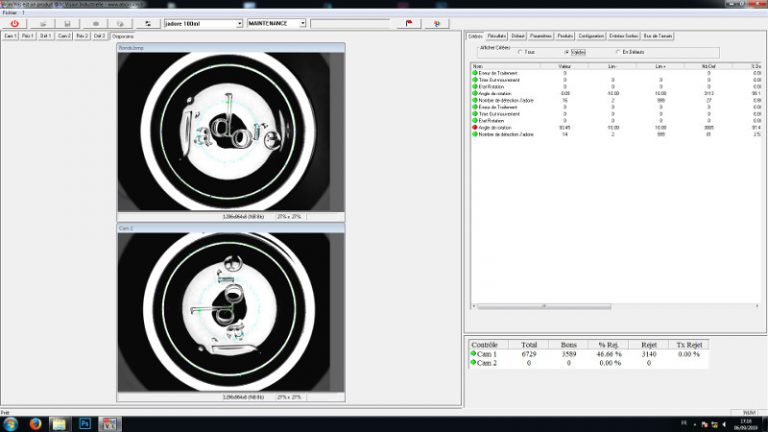

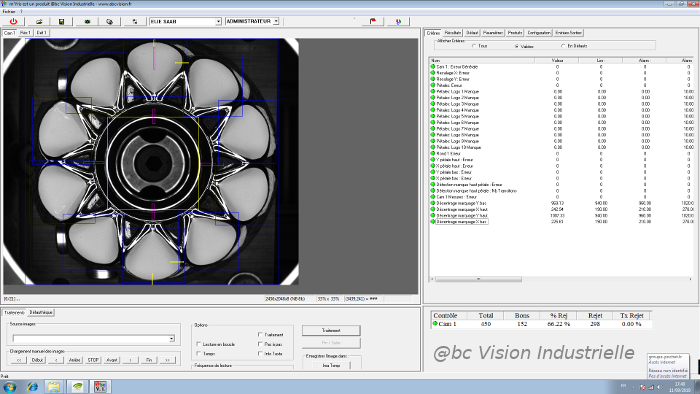

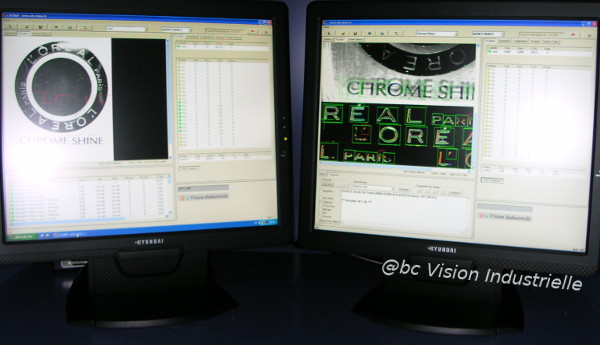

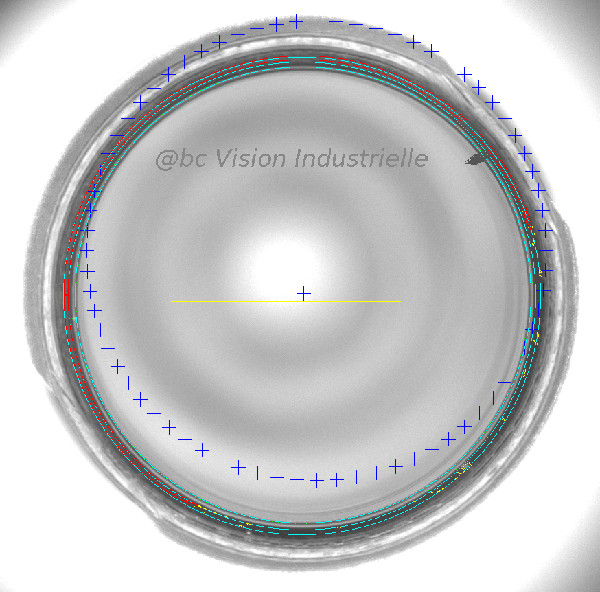

Aspect, logo, shape control... Brand image and products quality guaranteed.

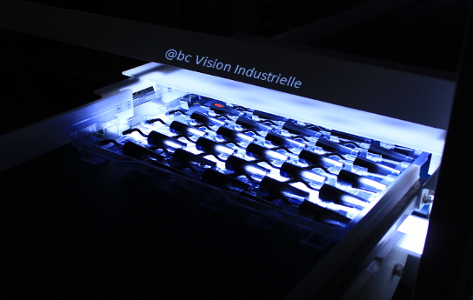

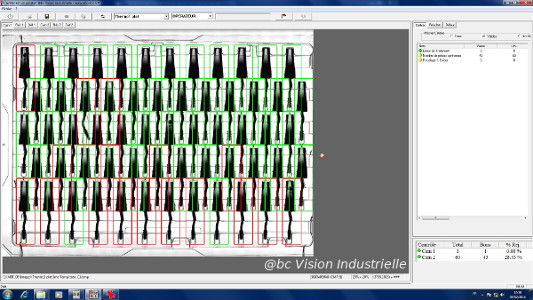

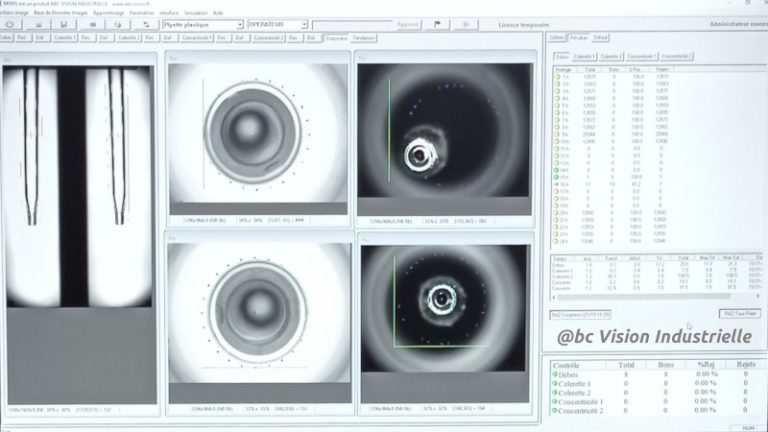

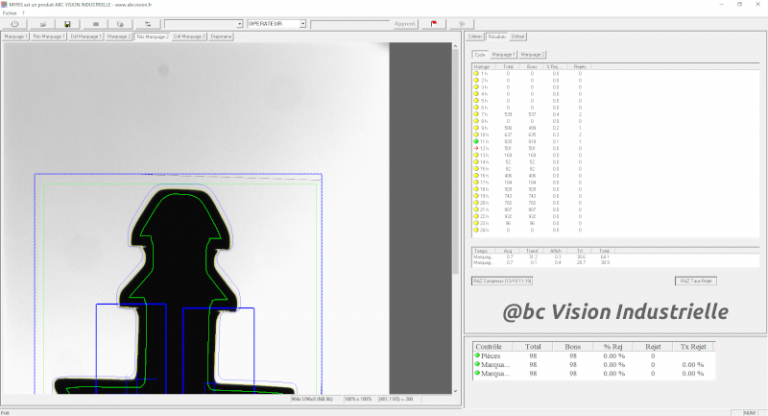

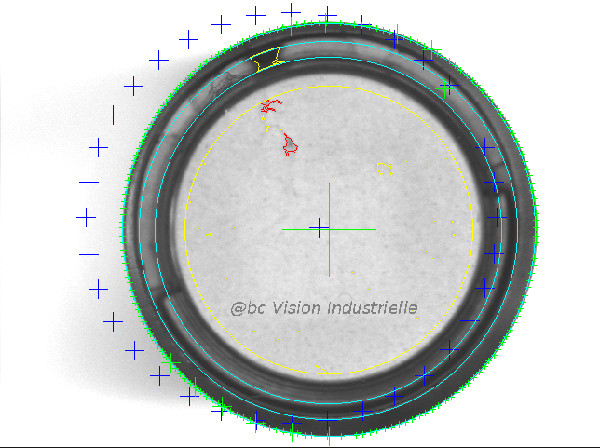

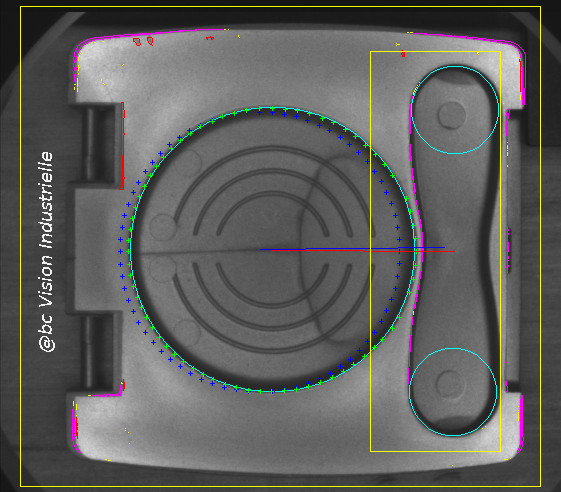

Cosmetic sector needs an infallible control to certificate quality products. Logo, decor, aspect, shape… everything needs to be perfect.

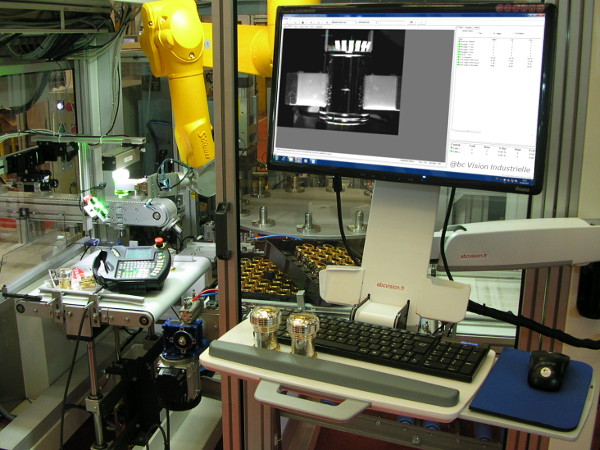

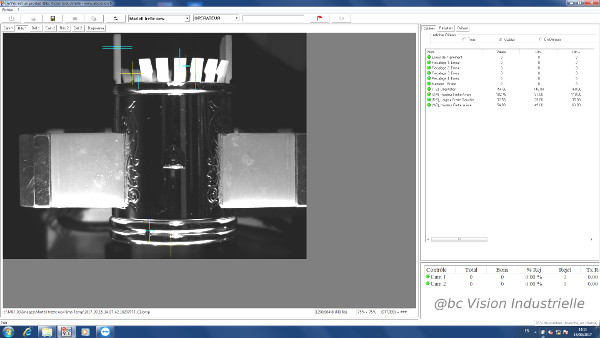

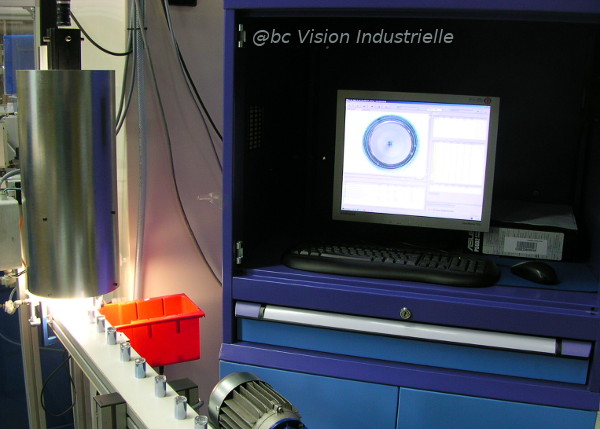

Vision control systems allow manufacturers to inspect their production while maintaining high rates. This technology contributes to optimize productivity and production quality, increasing the production yield.

Besides, traceability bringing by our systems is helping to fight against counterfeiting and to preserve a world-renowned “savoir-faire”.