Extremes conditions that make Vision control necessary.

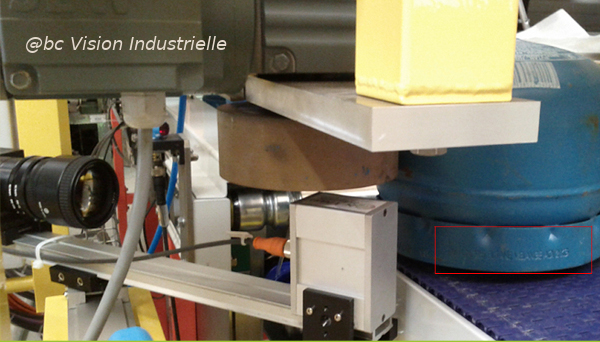

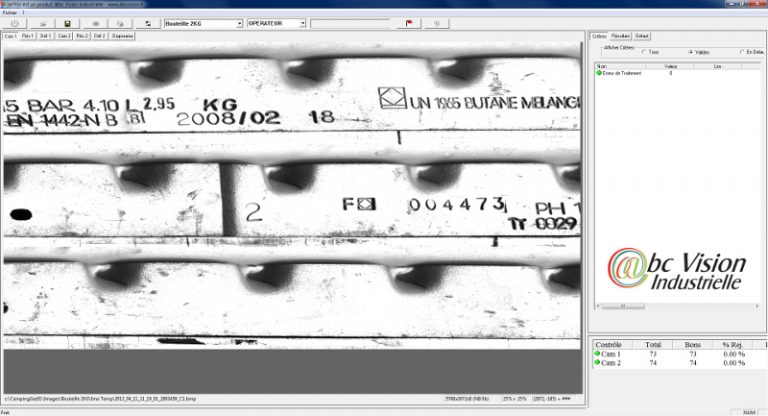

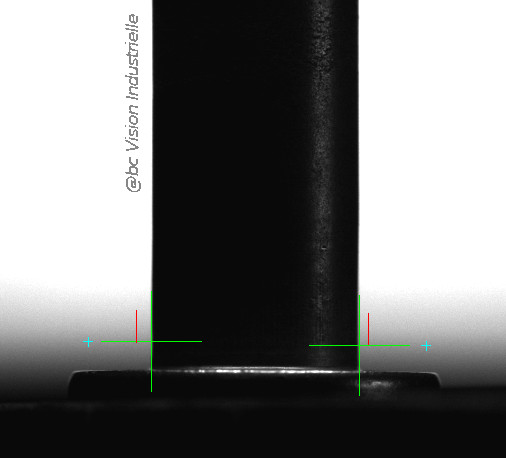

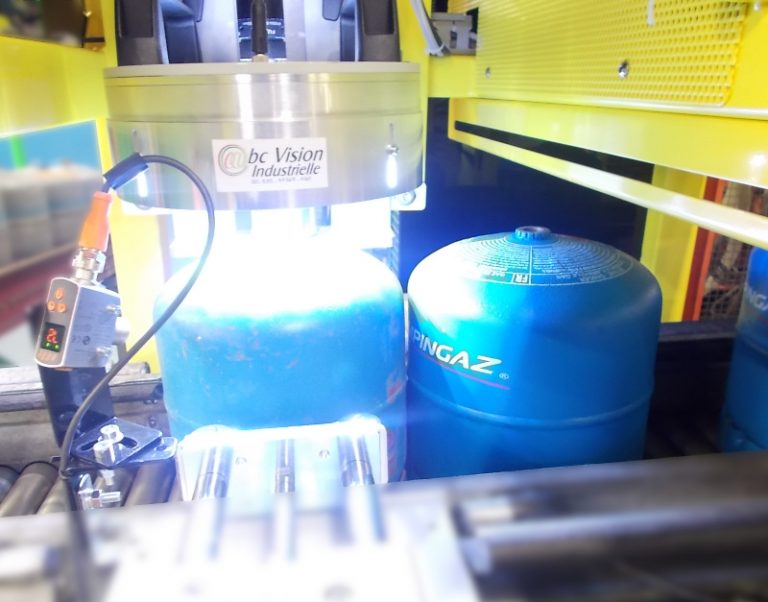

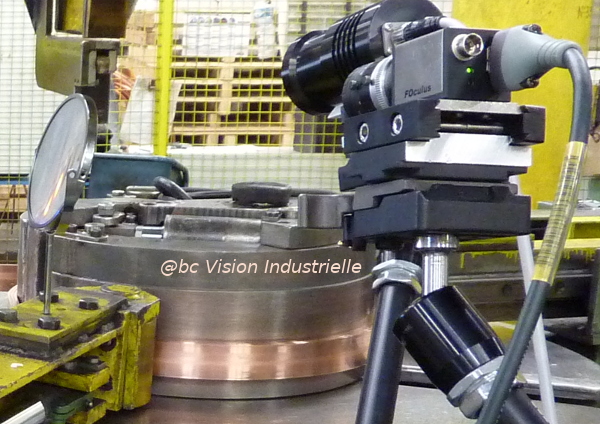

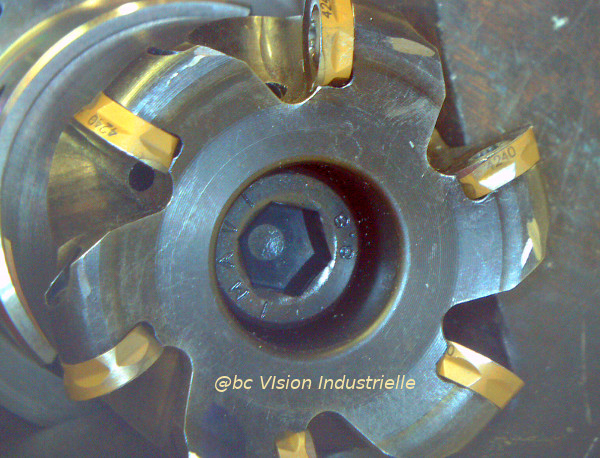

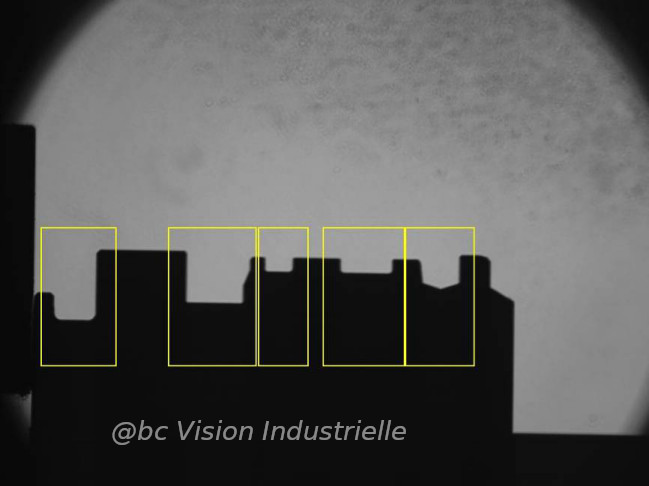

Metallurgical sector implies extremes fabrication conditions: foundry or furnace temperatures, projections, access or visibility difficulty, dust, mesure precision…

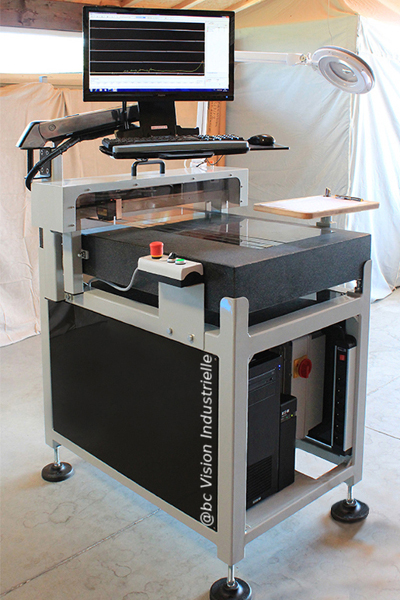

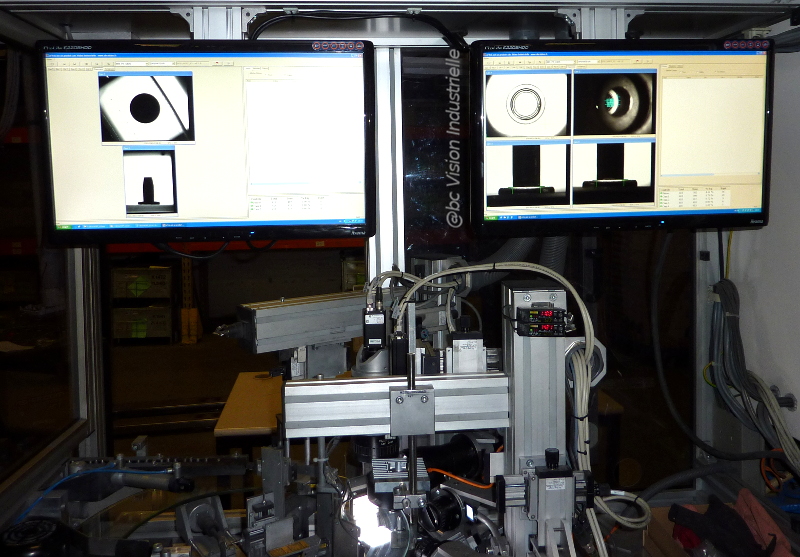

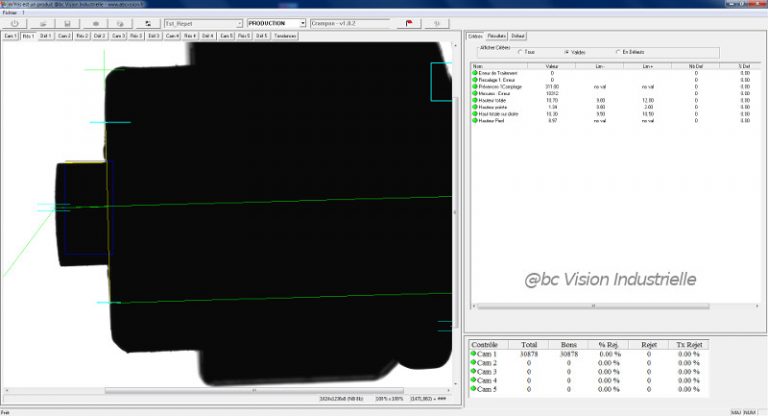

Machine Vision appears to be necessary to realise an efficient production control. Also, it assures the security of technicians.

Thanks to a close partnership with the customer, we can face technical challenges imposed by the sector and conserve the “savoir-faire” on our territory.